Modern medicine is experiencing a transformative era, where emerging technologies are redefining traditional healthcare practices. One such innovation is 3D printing, a technology that has found a diverse range of applications in the medical field. This article explores the use of 3D printed organs in medical training and discusses their potential future applications.

The Advent of 3D Bioprinting in Medicine

The integration of 3D printing into the medical field is revolutionizing healthcare practices. This technology, widely known as bioprinting, is the process of creating cell patterns in a confined space using 3D printing technologies, where cell function and viability are preserved within the printed construct.

Also to see : What Are the Psychological Effects of Long-Term Space Travel on Astronauts?

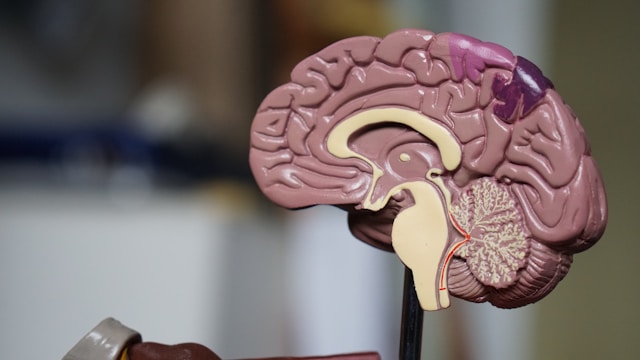

The use of 3D printing in medicine has been documented in numerous scholar journals, available on platforms such as Google Scholar and PubMed. The driving force behind this technology is the ability to create customized models of human organs. For medical professionals, these models offer unprecedented opportunities to study and understand the complex structures of human anatomy.

Medical Training with 3D Printed Organs

In medical education, the traditional approach of cadaver dissection has been the cornerstone for teaching anatomy. However, this method has its limitations – cadavers are not always readily available, and they do not fully represent the variety of pathological conditions that doctors may encounter.

Topic to read : What’s the Latest Research on the Health Benefits of Kombucha?

This is where 3D printed organs come into play. Medical educators are now using 3D printed organs as tissue and organ models, which serve as an effective teaching aid for students. The 3D printed organs are an exact replica of the patient’s organ, with all anatomical details accurately represented. This provides the students with a hands-on, interactive learning experience, enhancing their understanding of human anatomy.

Moreover, these 3D printed models can be used for surgical planning and rehearsal. Surgeons can practice on these models before the actual surgery, improving surgical outcomes and reducing the risks involved.

Materials Used for 3D Organ Printing

The choice of materials used for 3D printing organs is critical in ensuring the functionality and viability of the printed organ. These materials need to mimic the mechanical and biological properties of the natural organ tissue.

One of the commonly used materials is bio-ink, a substance made of living cells. This bio-ink is deposited layer by layer to form the desired organ structure. Other materials used include synthetic and natural polymers, ceramics, and composites. The selection of the material depends on the specific requirements of the organ to be printed.

Potential Future Applications of 3D Bioprinted Organs

While the current use of 3D printed organs is primarily focused on medical training and surgical preparation, the future potential of this technology is immense. The ultimate goal of bioprinting is to create fully functional organs that can be transplanted into patients.

There is ongoing research to achieve this goal. For instance, scientists are working on producing bio-inks that can be used to print organs with a higher level of complexity and functionality. These bio-inks would contain a mix of different types of cells, allowing for the creation of more complex tissue structures.

Another area of research is on improving the vascularization of the printed organs. Vascularization is the formation of blood vessels, a crucial component for the survival and functionality of the organ. Improved vascularization would enable the printed organs to integrate more efficiently with the patient’s body.

Embracing the Future with 3D Printed Organs

The integration of 3D printed organs into medical training marks a significant leap forward for modern medicine. This technology not only enhances medical education and practice but also holds the promise of addressing the shortage of organ donors in the future.

However, while the prospects are exciting, the development of fully functional 3D printed organs is still in the experimental stage. There are numerous challenges to overcome, from developing suitable materials to ensuring the printed organs function as intended.

Regardless, the progress made so far suggests that the day when 3D printed organs become an integral part of healthcare may not be too far off. As we continue to explore and fine-tune this technology, the potential benefits for both medical professionals and patients are boundless.

Advancements in 3D Bioprinting Materials and Techniques

A crucial component of 3D printed organs is the materials and techniques used in their production. The selection and combination of these elements can significantly influence the viability and functionality of the printed organ. The materials, commonly referred to as bio-inks, need to mimic the mechanical and biological properties of natural organ tissues. Most bio-inks are made of living cells which are deposited layer by layer to create the organ structure. Moreover, other materials such as synthetic and natural polymers, ceramics, and composites are used based on the specific requirements of the organ to be printed.

One of the significant advancements in the field is the development of multi-material 3D bioprinting. This technique uses multiple materials simultaneously during the printing process, resulting in a printed structure with varying properties in different areas. This allows for a high degree of customization, enabling the creation of complex structures that closely resemble natural organs.

Recent articles on PubMed and Google Scholar have reported on the use of novel materials and techniques in 3D bioprinting. For instance, researchers are experimenting with new types of bio-inks that can support the printing of more complex and functional organs. Such advancements are opening new frontiers in the field of regenerative medicine and personalized medicine.

With the rapid advancements in 3D printing technology and materials, the line between natural and printed organs is becoming increasingly blurred. However, challenges persist, especially regarding the vascularization of printed organs, i.e., the formation of blood vessels. Enhancing vascularization is critical as it enables the printed organs to integrate better into the patient’s body, enhancing their survival and functionality.

Regulatory and Ethical Considerations in 3D Organ Printing

As with any new technology in healthcare, 3D printed organs present some regulatory and ethical issues. The medical community, regulatory bodies, and policymakers are grappling with these challenges as 3D printed organs move closer to becoming a reality.

In terms of regulation, there is a need for a comprehensive framework to oversee the safety and efficacy of 3D printed organs. This includes ensuring that the printing technology and materials used are safe and that the printed organs function as intended. Free articles on PMC and Google Scholar highlight the importance of rigorous testing and clinical trials in establishing the safety and effectiveness of these medical devices.

Ethically, questions arise about the availability and accessibility of 3D printed organs. As with organ transplantation, there is the potential for disparity in access to 3D printed organs, with wealthier patients potentially having better access than others. Concerns also exist about the commodification of body parts and the potential for misuse of this technology.

Regardless, the consensus is that the potential benefits of 3D printed organs far outweigh the challenges. These include addressing the shortage of organ donors, improving patient outcomes, and advancing medical education and training. However, it is crucial that these benefits are realized in a manner that is ethical and equitable.

Conclusion

The integration of 3D printed organs into medical practice is transforming healthcare as we know it. The ability to create customized organ models is improving medical education and surgical outcomes. Moreover, the potential of this technology to address the shortage of organ donors is immense.

However, the journey towards fully functional 3D printed organs is still ongoing. Challenges persist, including the need for better materials and techniques, improving the vascularization of printed organs, and addressing regulatory and ethical issues. Despite these challenges, the progress made so far is encouraging, and it is only a matter of time before 3D printed organs become an integral part of healthcare.

As we continue to explore and fine-tune 3D bioprinting technology, the possibilities for its application in medicine are boundless. From training future doctors to performing personalized medicine, and from enhancing surgical preparation to revolutionizing organ transplantation, 3D printed organs are set to redefine healthcare in the 21st century. As of 19/04/2024, this technology remains a beacon of hope for millions of patients worldwide.